Raspberry Pi cuts product returns by 50% by changing up its pin soldering

Raspberry Pi cuts product returns by 50% by changing up its pin soldering

Raspberry Pi cuts product returns by 50% by changing up its pin soldering

Raspberry Pi cuts product returns by 50% by changing up its pin soldering

Raspberry Pi cuts product returns by 50% by changing up its pin soldering

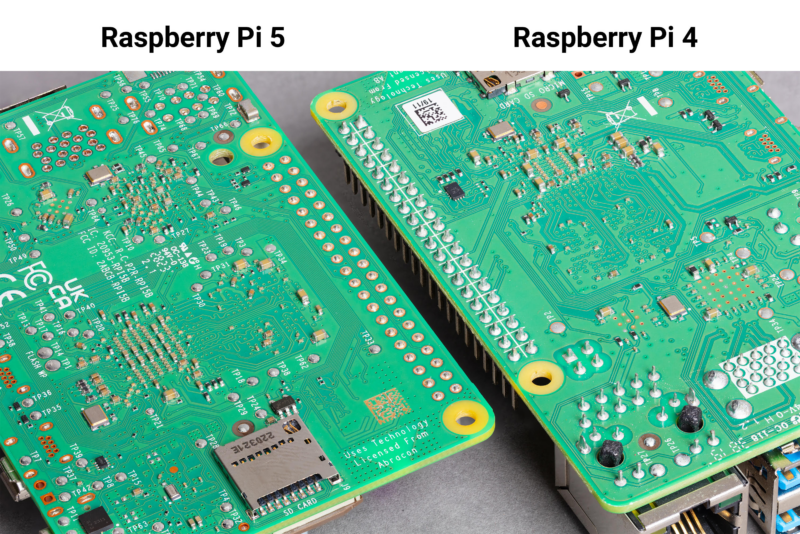

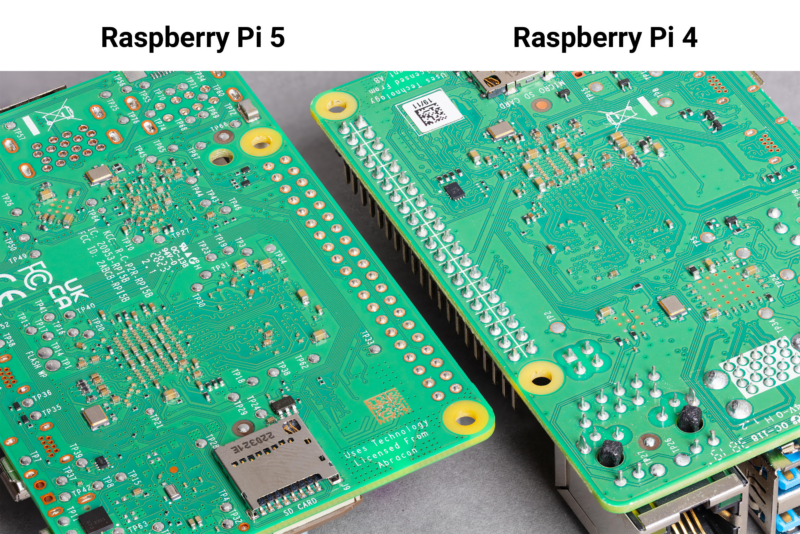

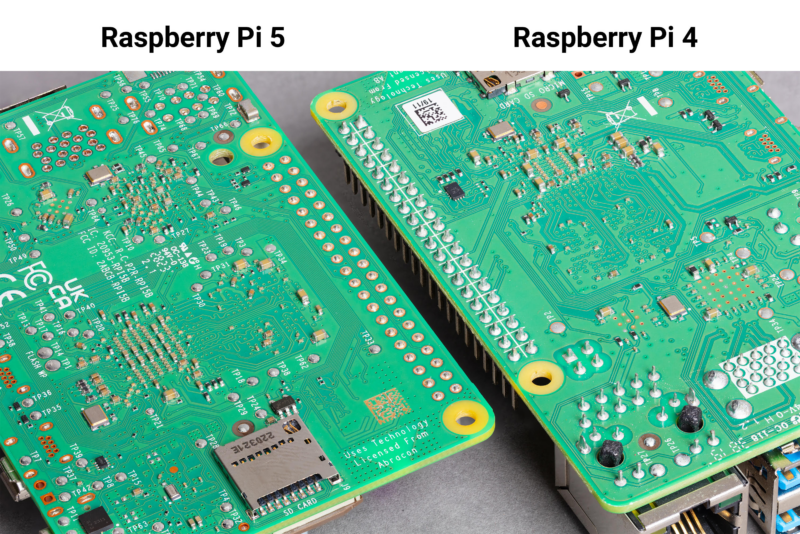

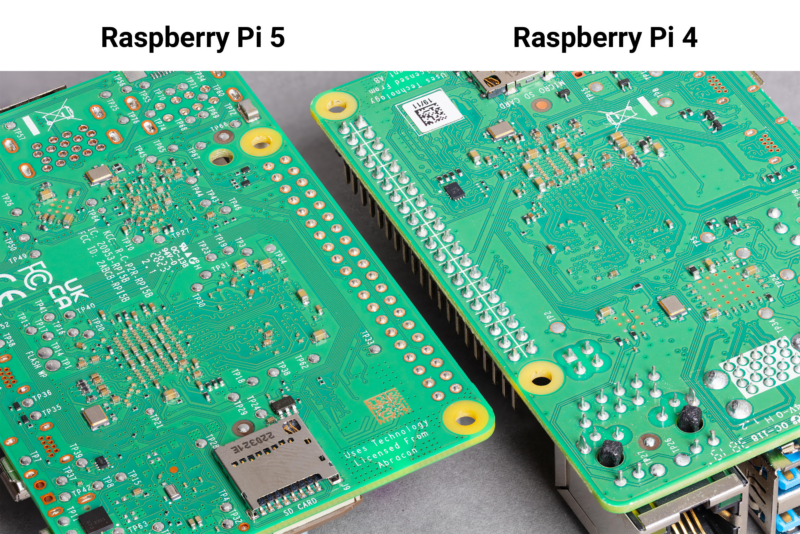

They now use intrusive soldering that solders surface mount and through-hole components at the same time:

The idea behind intrusive soldering, also known as pin-in-paste soldering is simple: solder paste is printed onto or around a through-hole pad, and the through-hole component is passed into reflow with your SMD components. The molten solder paste then fills in the through-hole and attaches the component pin.

I used to work on an SMT line, and pin in paste was the bane of my fucking existence. The parts (mainly connectors) were rarely within tolerance, and a leg or two would consistently miss their holes, if not outright rejected by the inserter.

So if I'm reading that right - higher failure rate on the line but those that passed I'd imagine have a higher rate of success?

So, would your suspicion be that it's causing them more failed boards in production?

I guess if it's reducing returns, that might be something they're accepting as a tradeoff?

How long ago was this? Could the process have become more acurate in the time you've been away from it?

I was really confused by the headline for a minute until I realized they were talking about products returned instead of profits returned.

Cool stuff!